The duct burner for dry serves as a core component in modern industrial heat source systems, with extensive applications across coating drying rooms, seed drying, fertilizer processing, and panel drying operations. Known for its high efficiency, energy savings, and environmental performance, it has become a vital technology driving industrial upgrades. As the demand for industrial drying continues to grow, the combination of innovative design and reliable natural gas compatibility makes duct burners an increasingly attractive solution.

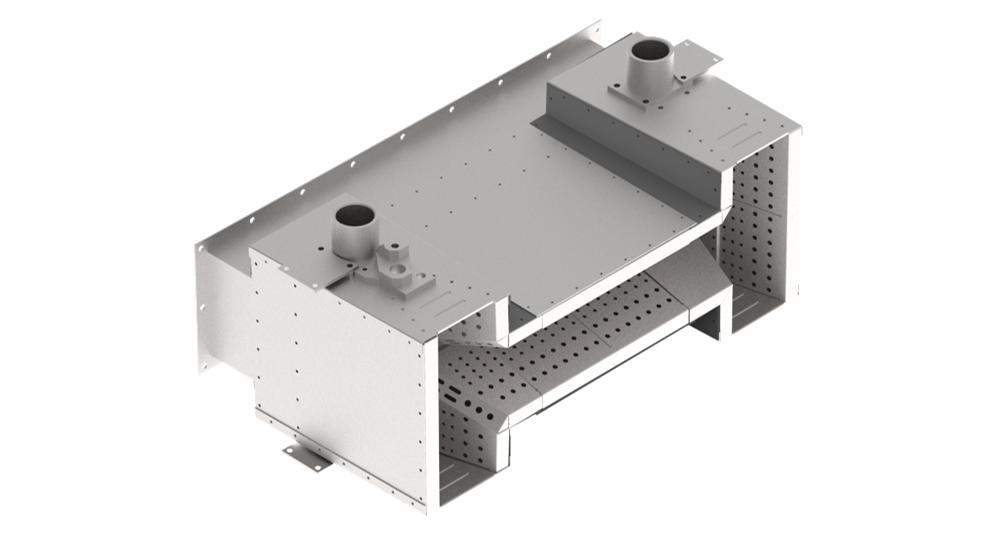

(Duct Burner for Drying)

In coating and painting drying rooms, duct burners for dry play an essential role. Coating production lines require extremely precise and stable temperature control. Duct burners provide uniform hot air output, facilitating rapid curing and consistent surface quality. When powered by natural gas, combustion is clean and efficient, with minimal pollutant emissions, aligning with modern environmental standards for coating processes.

Seed drying represents another critical application in agricultural processing. Duct burners for dry allow adjustable air temperature and flow rate, enabling efficient and gentle drying that preserves germination rates. The use of natural gas as a fuel source ensures stable thermal performance and helps reduce operational costs, making these systems ideal for large-scale seed processing facilities.

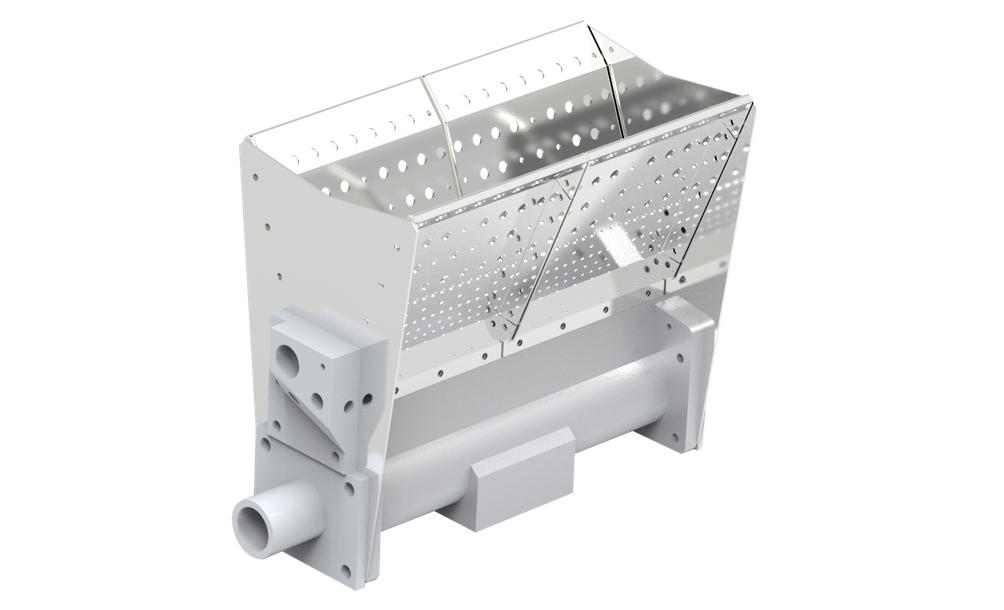

(Duct Burner for Fertilizer Drying)

In fertilizer drying, duct burners demonstrate remarkable flexibility. Different materials, including organic and compound fertilizers, require specific drying temperatures and durations. Intelligent control systems allow precise regulation of combustion conditions. The reliability of natural gas enables consistent performance throughout extended production cycles.

Within the panel drying industry—especially for wood and engineered wood products—duct burners offer a consistent and dependable thermal solution. High-temperature hot air rapidly extracts moisture while minimizing risks of warping or cracking. Natural gas provides a stable and efficient energy source, ensuring product quality while enhancing operational economy.

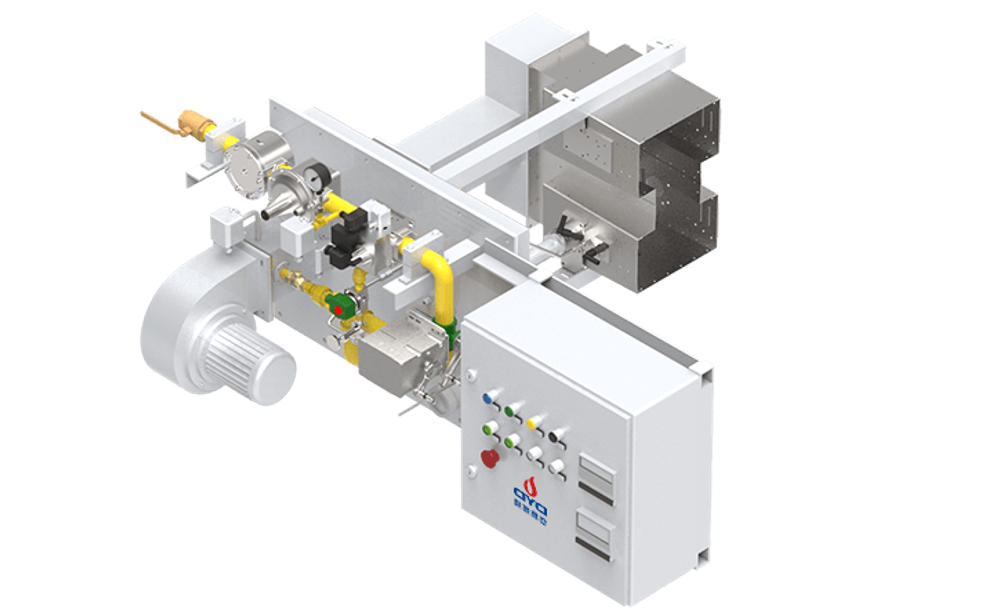

(Duct Burner Combustion System)

Modern duct burners for dry are specifically optimized for natural gas operation. This single-fuel focus allows for maximized combustion efficiency and simplified system integration. The use of natural gas ensures lower emissions and reduced environmental impact compared to other traditional fuel sources. Furthermore, the stability and wide availability of natural gas make it an ideal energy source for continuous industrial drying processes.

In summary, ongoing innovation has established duct burners for dry as indispensable equipment in industrial drying. Their versatility and optimized natural gas operation provide efficient, eco-friendly thermal solutions for sectors including coating, agriculture, and materials processing. As sustainability requirements become increasingly stringent, natural gas-powered duct burners for dry are poised to lead the transition toward intelligent, green industrial drying technologies.